At Ehcolo we manufacture 15 types of palletizers. We want your production to be the most successful it can be and therefore, we offer no downtime, high quality products and a good investment that provide you efficiency. We are a leading palletizer manufacturer with over 33 years of experience, so we know how important quality is and can guide you to the best palletizing solution for your company, that enables you to achieve effective and sustainable benefits.

Capacity: 100-2500 bags/boxes per hour

Weights: 2-50 kgs

On all sizes of pallets and pallet heights

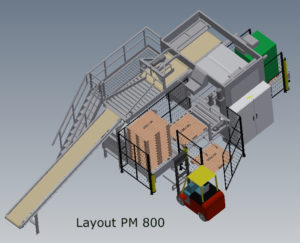

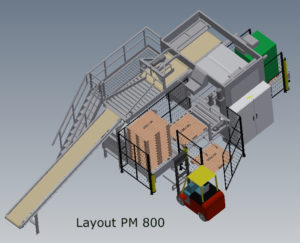

PM 800 is our stripper plate palletizer, and we can supply 9 different models for different capacities up to 2500 bags or boxes per hour. With its unique layer side and top pressing facilities, it palletizes straight sided, stable and beautiful looking pallets, well suited for high storage stacking and safe transport.

The PM800 palletizer can handle bags and boxes of any type or size. It can also palletize on any pallet size. Without question, the most accomplished and reliable palletizer on the market. Our PM800 is the only palletizer in the world where all movements/motors are fully servo controlled and giving a very controlled soft start and stop, also a unsurpassed accuracy and long life.

Low energy: Every time one of the motors is slowing/braking down and coming to a stop, the braking power is re-used, thus saving you 20% energy compared to other palletizers. Our palletizers are green and we care about the environment.

Our modern and automated palletizer provides stability, precision and operates at a high speed, which increases the productivity while improving safety standards. PM 800 palletizer series contributes to a high-volume shipping and storage. We have customers all over the world that have achieved success with our palletizers. Ehcolo simplifies a process that can be complex and creates a smooth automation for your need.

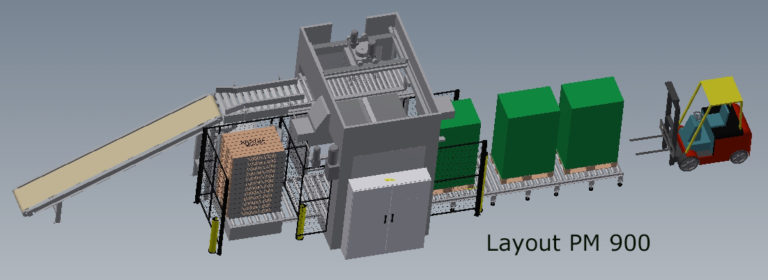

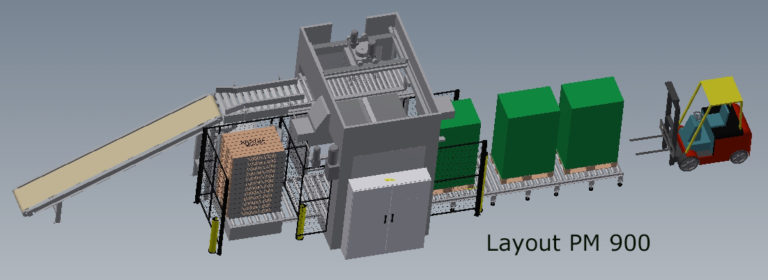

PM 900 is our combined stripper plate, gantry robot palletizer, and we can supply 3 different models for different capacities, up to 1800 bags per hour.

The PM 900 can palletize bags side-by-side, as the PM 800 but also overlapped. Ideal for not fully filled bags and bags which has a sensitive surface. With its unique layer side and top pressing facilities, it palletizes straight sided, stable and beautiful looking pallets, well suited for high storage stacking and safe transport.

The PM 900 palletizer can handle bags of any type and size. It can also palletize on any pallet size. Without question, the most accomplished and reliable gantry type palletizer on the market.

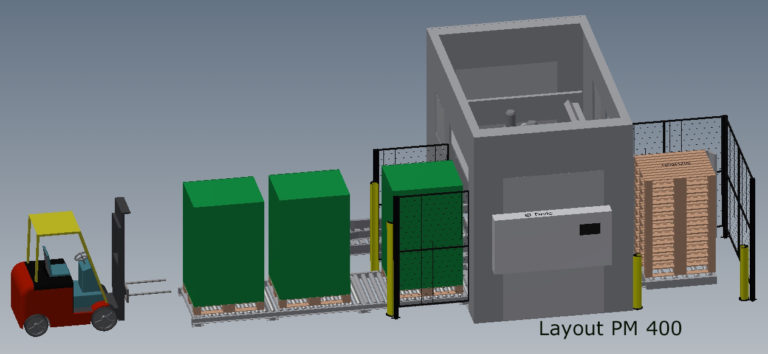

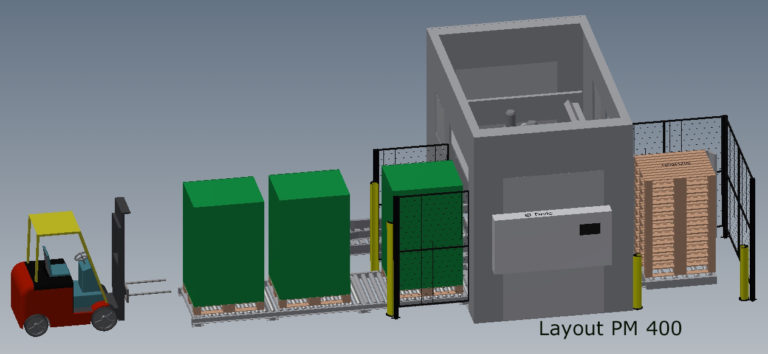

Our low-level gantry robot palletizer, designed for low and medium capacity packing lines up to 400 bags per hour. We supply 2 models, one semi-automatic, in that way, that pallet exchange is manual, so low investment. The other with automatic pallet exchange and full pallet conveyor.

The unique side bag pick-up system with a top press plate gives straight-sided, stable and beautiful pallets suitable for high storage stacking and safe transport. Can palletise bags side-by-side and also overlapped as the PM 900. Small footprint. Our only type, where motors are still frequency converter controlled.

Our state of the art robotic palletizer is from Yaskawa, where Ehcolo designs and manufactures the gripper and conveying systems for both product and pallets. NEW is our own developed touch screen control with easy control and set up of pallet patterns, which makes it very easy to use.

Our current customers/operators are extremely happy about this new development. It can palletize both bags and boxes with a capacity of up to 1200 bags/boxes per hour with single bag handling, higher with multi bag handling.

Our robot do not have the layer side and top pressing facilities as our model PM 800 and PM 900, but does a decent job, when bags are firm. As supplier of all types of palletizers, we have no strings regarding recommending the right palletizer for you.

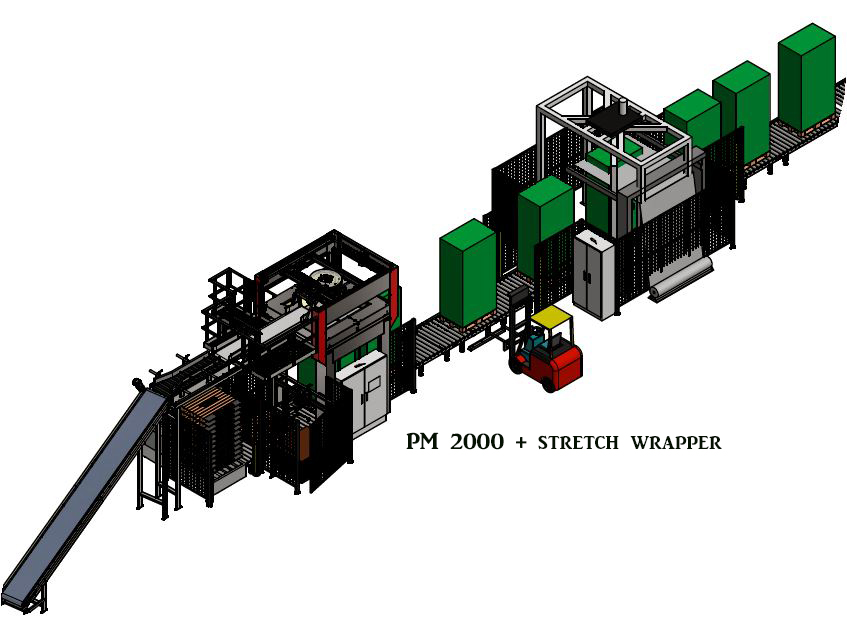

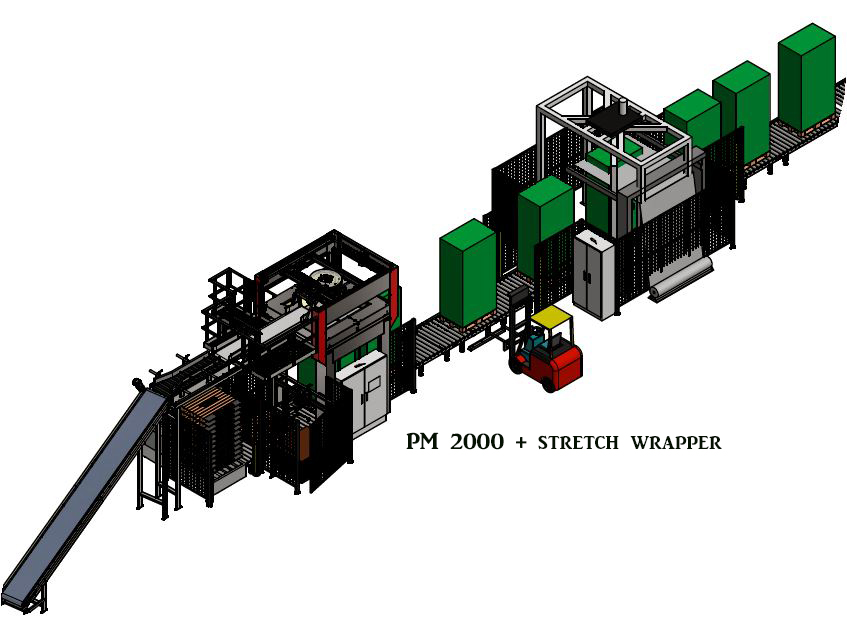

PM 2000 is a new developed combined stripper plate and gantry robot palletizer, which covers a capacity range from 1000 to 2000 bags per hour, highest capacity at many bags per layer.

The PM 2000 can palletize bags side-by-side, but also overlapped at same high capacity. Ideal for not fully filled bags and bags which has a sensitive surface. With its unique layer side and top pressing facilities, it palletizes straight sided, stable and beautiful looking pallets, well suited for safe transport and for display at end customers.

The PM 2000 palletizer can handle bags of any type and size. It can also palletize on any pallet size. Without question, the most accomplished and reliable gantry type palletizer on the market.

And the PM 2000 as our other palletizers is the only palletizers in the world, where all motors are fully servo controlled and giving a very controlled soft start and stop, resulting in unsurpassed accuracy, long life and very low noise.

Exceptional also, no use of expensive to produce compressed air.

Low energy: Every time one of the motors is slowing/braking down and coming to a stop, the braking power is re-used, thus saving you 20% energy compared to other palletizers. Our palletizers are green and we care about the environment.

We have developed a technology that saves energy when motors in the machine slow down or stop, which they do often as this is natural for a palletizing machine. This braking energy is re-used by other running motors reducing energy consumption by up to 20% compared to others. Contributing to a safer and healthier environment and economy. You can find the palletizer system, robotic palletizer or bag palletizer you are looking for, by contacting us. We offer our standard as well as tailor-made solutions.

> Ehcolo Low Energy Palletizing

“Anywhere Control” via Internet, Ehcolo supplied machines can be monitored and controlled from anywhere, and we can monitor and access everything, also the history of events, so that we remote and easily can make eventual diagnostic work and in fact also operate the machines, change parameters and eventually also change/improve software remote.

IoT (Internet of Things) ready.

Our palletizer control has a OPC-UA server, which is the newest within data communication, many does not know it, but everybody will need to know and use, as this is the future way to do it and an easy way and well documented. In short, we can make available all thinkable data and then they can be captured by customer SCADA system in a format customer can easily handle. We just have to agree on which data you are interested in.

Gears with servo motors and normal geared motors.

We only use SEW motors and we are not used to any breakdown of any SEW parts, but should something happen in the future, the parts are normally available locally.

All motors are servo controlled, absolutely not normal, and has some costs also, but all items have soft start and stop, this extend life time many times and also very low noise.

NEW: is a newly developed “Ehcolo Preventive Maintenance Module” EPMM, which records operating times, driving length, number of start and stops, numbers of activation of sensors, temperatures, etc. etc., on every single item, resulting in informations/messages automatic on the touch screen, like time for maintenance and preventive service, all in order to minimize downtime.

Our address

Ehcolo A/S

Smedevej 10, Toboel

6683 Foevling

DENMARK

Follow us

Ehcolo

Telephone +45 75 39 84 11

E-mail: post@ehcolo.dk